We didn’t set out to make our surfaces by hand. Honestly, we thought this business would be way simpler. Our original plan? Send off our designs to a third-party printer, get back a perfect product, ship it to you, and call it a day.

But that’s not how it went.

We tested printers across the country—several of them. And every single time, the results came back looking flat, muddy, or just… wrong. The texture we’d worked so hard to create didn’t translate. The colors were off. And every printer eventually dropped us for being too “particular.” (Which is a nice way of saying we wanted the work to actually look like the art we made. Go figure.)

Right around the time we were about to throw in the towel, a friend of a friend in the print world encouraged us to try printing in-house. We tested it—and the results were exactly what we had envisioned all along: rich texture, accurate color, and artwork that actually looked like what we designed.

Finally.

Of course, that was just the beginning.

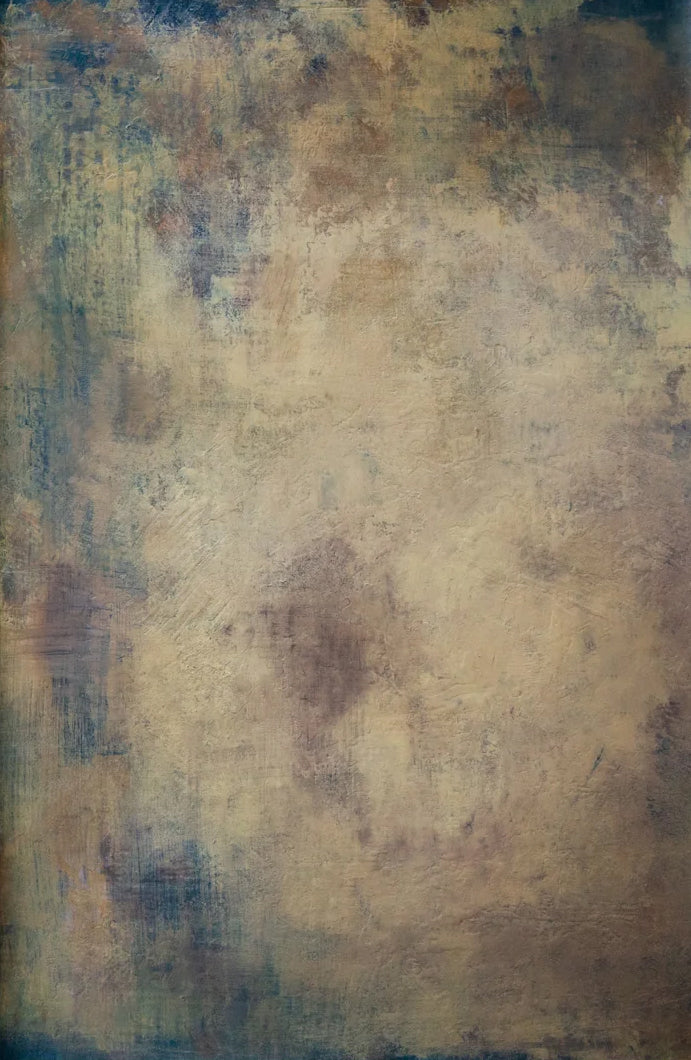

Turns out, the material that gave us the print quality we loved? It was also incredibly fragile. So Joe—visual artist, co-founder, and eternal problem-solver—developed a process to protect every surface with a custom matte laminate. It doesn’t feel like plastic or have that slick, shiny finish you might be used to. Instead, our surfaces have a soft, tactile texture—just enough tooth to catch the light in a natural way, without pretending to be the exact material it’s mimicking. Wood doesn’t feel like wood. Stone doesn’t feel like stone. But the surface has depth, and that subtle texture makes a difference in how it photographs.

It’s not fast. It’s not easy. But it’s worth it.

Don't believe us? See the difference below.

The photos say it better than we could,

here's the reason why we do it all ourselves.

This is our Bella surface.

Use the slider to see the difference between how "they" made our surface versus when we did it.

how our rollable surfaces are made

• Joe creates an original painting in our studio, based on what I would want to shoot on as a photographer. (Except for the stone surfaces—those are actual stone, photographed so you don’t have to haul 80 pounds to your shoot.)

• I photograph the artwork, tweak it as needed in Photoshop, and prep it for printing.

• We print in-house using our wide-format printer, then let the print cure for 24 hours so the ink fully sets.

• Joe applies our matte laminate—by hand, one print at a time. It’s a multi-layer process, with drying time in between and careful smoothing to get it just right.

• Every single print gets a final quality check, a soft cloth polish, and then it’s packed and shipped from our studio to yours.

It’s a process that takes time, attention, and more than a little patience. But it shows.

You’ve probably used vinyl backdrops before. But you haven’t used one like this. We’re not outsourcing. We’re not mass-producing. These are handcrafted photography surfaces—created by a photographer and a painter who obsess over every detail because we actually use them ourselves.

This wasn’t the business model we imagined when we started.

It’s better.